25-01, Jalan Bayu Puteri 1/3,

Taman Bayu Puteri,

80150 Johor Bahru,

Johor, Malaysia.

+607-3318892

+607-3329892

Reliacon was the design consultant worked together with the roof structure subcontractor. Total steel weighted more than 6,000 ton. | |||

JB CIQ roof |  External view of the upper roof with steel truss nearly completed. |  Internal view of the light vehicle area. |  Typical base connection between tree columns and RC structure. |

Reliacon did the tender design for the subcontractor to work out the costing and won the design and build tender. The main roof structure could not be designed in partial, a 3D structure model was required for the analysis and design the whole roof as one. The model consisted of more than 6,500 members. | |||

JBS steei roof |  Overall view of the main entrance roof |  Complicated entrance roof structure. |  Complicated circular hollow section connection |

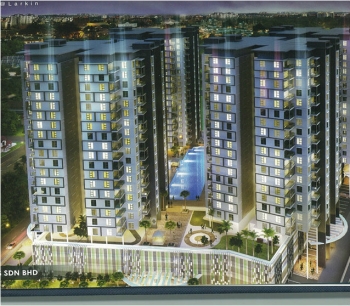

Architectural impression. |  Constructing |  Overall view of the computer model of the two condominium towers with link bridge |  Zoom-in view of the structure model of the link bridge levels |

Architectural impression view |  Architectural impression view |  Constructing view |  Band beam design was used to create long cantilever slab |

M-Condo | |||

34 blocks, fully precast except cast in-site ground slab, 4 storey walk up apartment. Foundation types included piled and strip footing on grade depending on soil conditions. | |||

Precast items delivered to site. |  Precast panel being erected. |  Half way erected. |  Nearly completed building with roof installed. |

This was the first shear wall design by local structure consultant and contractor. RELIACON worked together with the contractor to convert the original beam-column design to shear wall design for the purpose of optimizing the construction cost. This project consisted 8 blocks of 10 to 13 storey apartment. | |||

Completed building | |||

This wall an abandoned project with pile cap and up to almost half building height structure done. Reliacon worked together with the new developer to redesign and complete the project. | |||

Medium cost apartment |  Low-medium cost apartment | ||

This project consisted 4 blocks, 698 units, of apartment. The structure was originally a beam-column design, RELIACON worked together with the contractor to convert the design to shear wall structure to reduce the construction cost.

Due to open area needed at the ground floor, and the ground floor height was fixed eliminating the possible use of transfer beams, the shear walls are used as deep beams to transfer the load to the columns. The 1st floor beams exposed in ground floor are all ordinary beam sizes. | |||

Overall view of the completed project. |  Side view of the buildings |  Front view of the building, notice that there is no big transfer beam. | |

The structure is a full RC shear wall design, using alluminum form work, with transfer beams system. | |||

Completed Sky Suites | |||

High value condominium | |||

High value condominium | |||

Double storey low-medium cost terrace house on swamping land.

Use of RC shear wall reduced the intensity of the building load distribution. The reduced load intensity allowed the use of properly designed bakau pile foundation in the swamping land. Bakau pile could be the best and easiest to construction with the lightest most machine; and yet was the cheapest choice. | |||

Merging of pile cap with the ground slab allowed a single concrete casting to complete the foundation and ground slab |  Shear wall construction |  Use of simple stair stringers | |

This is a value engineering design project and also the 1st use of RC shear wall in the real sense of a vertical load taking structure. There are 241 units of double storey medium cost terrace house with RC wall and footing at grade Using RC shear walls as the vertical load taking members, the concentrated column loads are redistributed along the walls. this then allowed very economical and easy construction foundation design. Merging the footings with the ground slab and omitting ground beam, speed up the ground structure construction. The ground slab casting were done in 8 day time after completion of earthwork platforms. Use of RC shear walls on the 1st floor to 'hang' the 1st floor slab, eliminate the need of edge beam around the staircase opening. | |||

Completed building |  1st floor RC shear wall being constructed. |  One concrete casting completed all under ground structure together with the ground slab |  Use of 1st floor shear wall to hang the 1st floor slab eliminate beam at the edge of staircase opening. Help to reduce construction cost and improve clear ceiling height. |

52 m tall refinery tower structure. | |||

| |||

Steel pipe bridge supporting pipes which connect two major petrol refinery plants. | |||

| |||

Henritex S/B, Simpang Renggam | |||

CK Galvanizing S/B, Pasir Gudang | |||

Infinity at Tanjung Bungah |  Gold Coast Morib Resort |  5 Blocks of Apartment, Serdang |  Serina Bay |